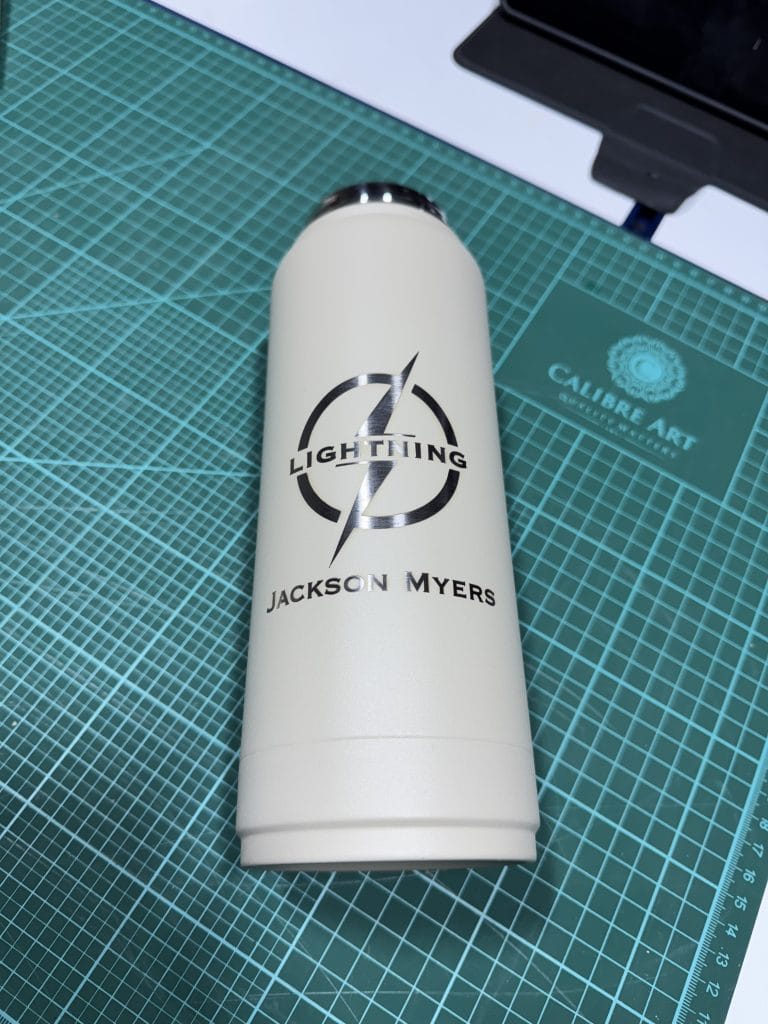

I laser engraved water bottles for my sons’ soccer team, the Lightning of the Colorado Ice Soccer Club.

Background

Both of my sons have been on the team for four years, they’ve become good friends with many of their teammates, my wife and I are super happy with the head coach (a pastor IRL), and I was tapped to be an assistant coach this season. Plus, this is the last season for the Lightning. The head coach is “retiring” from soccer and many of the boys are moving on to other teams or sports.

I wanted the boys to have something tangible that linked them as Lightning team members. Though the team has always called itself Lightning, it was only verbal recognition. On the Colorado Ice website, teams are listed by the coach’s name and the age group, “Derek Jones 2011B.” No offense to the coach, but that’s a hard name for 11-13 year old boys to rally around!

Logo Development

I started by creating a team logo in Adobe Illustrator. I’m still learning this tool and am surviving by making minor edits to pre-existing digital artwork. In this case, I searched for “lightning logos” and picked one I liked. After playing around with different fonts, I decided to use Copperplate. I ran a couple of proofs by my boys and they helped me settle on the final version below.

Laser Engraving Water Bottles

I use xTool Creative Space (XCS) to set up projects on my xTool P2S (55-watt CO2 laser). The settings are saved in the project (and shared below), so I just needed to add the player’s name below the logo for each water bottle. I let the players give me the water bottles, so I got some good experience working with a variety of brands and sizes, some more used than others. It added a bit of setup time with the rotary accessory, but that too was good experience.

| Setting | Value | Notes |

|---|---|---|

| Power | 60% | If the water bottle was a lighter color, I dropped the power to 50% to prevent burn marks. |

| Speed | 200 mm/sec | You could also increase the speed to prevent burn marks but I didn’t try that. |

| Passes | 1 | I always do 1 pass when using the rotary accessory. |

| Lines | 200 lines/cm | I started at 100 lines/cm but ran into a case where the stainless steel looked, well, stained. It was nothing that a Magic Eraser couldn’t remove, but increasing this setting to 200 meant I didn’t have to use as much “elbow grease.” |

| Mode | Bi-directional | I always use bi-directional. |

Lessons

I’ve done plenty of water bottles before, but I still learned a few things:

- I let each boy give me their own water bottle to engrave. I just wasn’t in a position to donate my time AND buy every team member a water bottle. The risk I took was that I would nail every water bottle on the first attempt because I didn’t have any to sacrifice. It meant double- and triple-checking all of my measurements and thoroughly cleaning the surfaces.

- I tackled a wide variety of brands and learned there is some variation in the quality of the powder coatings. This is how I landed on 60% power. It’s likely higher than needed, but I needed to make sure the coating was completely removed the first time.

- As much as I wanted to use the exact same artwork on every water bottle, I couldn’t resist adjusting the size of the font for the player’s name to match the size of the water bottle. The bigger the circumference of the water bottle, the bigger the font. The rule of thumb I developed is that the width of the player’s name should be about one-third of the circumference of the water bottle. My rationale was that you should be able to read the player’s name without rotating the bottle to see all of it. And so, depending on the water bottle, the size of the font ranged from 18-24 point (Copperplate). To my eye, this looked about right.

Gallery

The boys would give me a water bottle at one practice and I would return it at the next. In my haste to get them done in a timely fashion, I didn’t always remember to snap a pic. But you don’t need to see all of them to get the idea. I also did a few for the coaches!

Conclusion

Every side hustler faces the challenge of when to do a job for free. From a business perspective, you try to limit the free jobs to those that have some prospect of bringing in paid jobs. In this case, once parents learned I had this side hustle, it immediately sparked discussions I’m confident will result in paid jobs later.

But honestly, this was something I wanted to do for the players and my boys, specifically. They don’t know it now, but I hope they’ll eventually realize what a great experience this was. I figure the odds went up with these custom, logo water bottles.